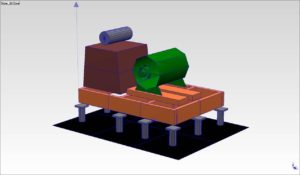

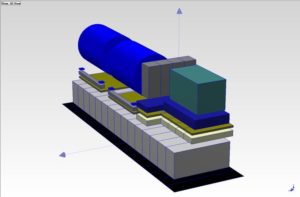

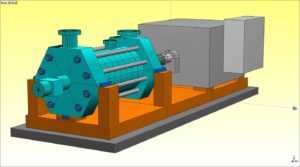

Modal/ODS Analysis – Often, industrial machines and especially the structures that they’re mounted on need to be studied thoroughly in order to precisely troubleshoot and solve problems. The usage of software animations greatly enhances the ability to “see” how a particular structure is responding to a particular excitation. In the case of Modal Analysis, the component and/or structure are excited utilizing a calibrated force such as from a shaker or impact hammer. Simultaneous response data is acquired that is used to generate frequency response functions and then transferred to modal software for animation. This test is performed with the equipment not in operation. The primary uses of Modal Analysis include:

- Identifying natural frequencies

- Identifying mode shapes

- Determining damping levels

- Verifying FEA designs

- Troubleshooting problem machinery

Operation Deflection Shape (ODS) testing is used to study the shape of a machine, structure, piping, supports, flooring, bracing, etc. during normal operation. The ODS test process is non-intrusive and will not interfere with normal production, as long as steady state operation is present. Phase and magnitude, measured from points on the machine and/or foundation are used to animate the motion of the machine. The primary uses of ODS testing include:

- Animate the shape of vibrating machinery

- Confirm vibration analysis problem type

- Identify weak structures

- Suggests system natural frequency

- Troubleshooting problem machinery

- Evaluate transient responses